-

Mobile Version

Scan with Mobile

- Member Center

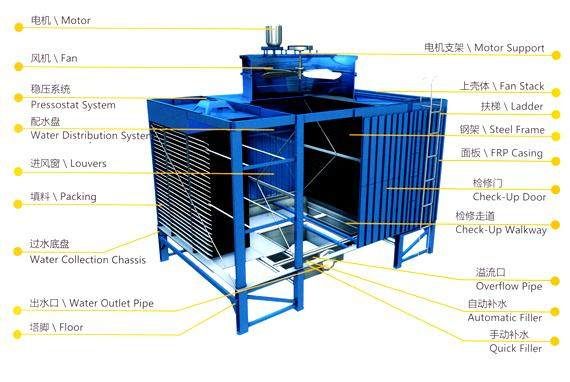

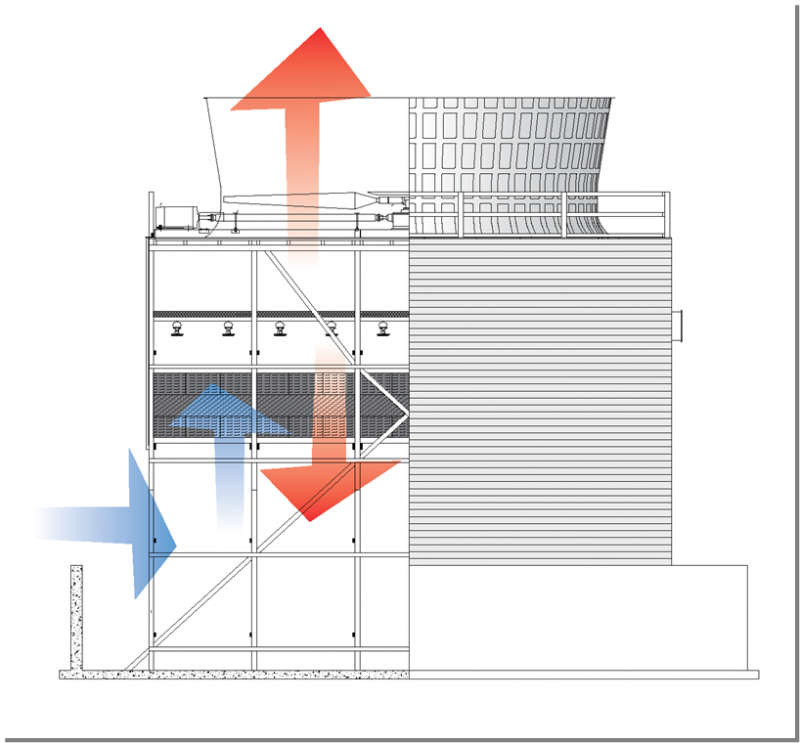

Square Cross Flow FRP Cooling Tower ODM &OEM Offered

Nothing beats the power of an excellent frp cooling tower. We are here to offer our clients with the best FPR square cooling tower to meets all their needs.

We are an FPR cooling tower manufacturer who engages in the manufacturing and supplying of the best cooling towers in the market. Our goal is to offer equipment that can enhance power, water and space saving to the users. The towers come with fixed headers and splash noozles which help in distributing water over the fills.

The cooling tower is made of pure high-grade fibreglass reinforced resin, which makes it durable and reliable regardless of the weather condition. The demanding users of this equipment are; diesel engine, process coolers, foam, leather, frozen series, and industrial cooling water among other uses.

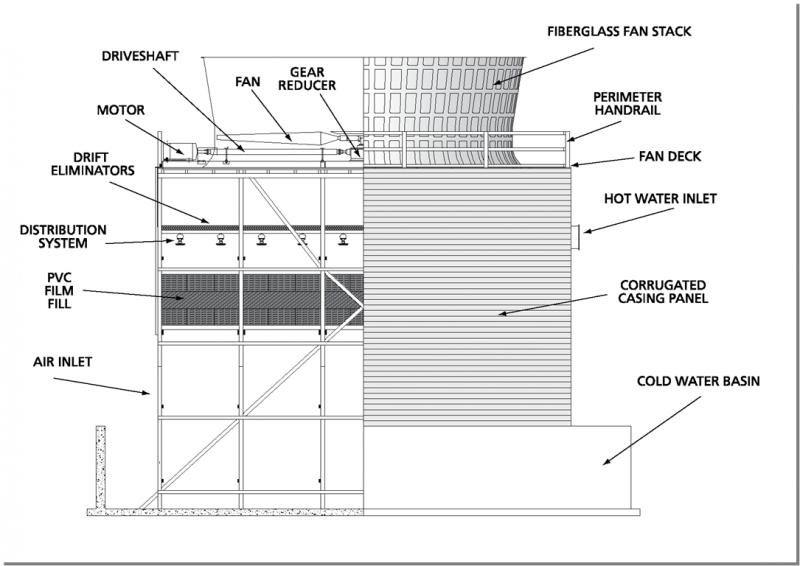

The cooling tower parts of FRP square cooling tower are:

Cast aluminium fan

These gravity fans are meant to help in the displacement of a high volume of air while they are light.

Cooling Tower PVC fills

This cooling tower PVC fill aims to help in enhancing heat transfer for maximum cooling.

Cooling tower splash nozzles

The FPR square cooling tower comes with cooling tower spray nozzles which help in hot water distribution in the cooling tower.

Motor

The cooling tower motor is meant for driving the fan.

| FRP Round Cooling Tower | ||||||

| Medol | NominalFlow(m3/h) | AirVolume(CMM) | Motor(kW) | (16M)NoiseLevel(dBA) | DryWeigh(Kg) | WetWeigh(Kg) |

| 8T | 6.23 | 70 | 0.18 | 45 | 46 | 190 |

| 10T | 7.81 | 85 | 0.18 | 46 | 49 | 199 |

| 15T | 11.7 | 140 | 0.37 | 47 | 60 | 298 |

| 20T | 15.62 | 160 | 0.55 | 48 | 80 | 320 |

| 25T | 19.51 | 200 | 0.75 | 49 | 110 | 540 |

| 30T | 23.4 | 230 | 0.75 | 50 | 135 | 550 |

| 40T | 31.21 | 280 | 1.5 | 52 | 150 | 590 |

| 50T | 39.24 | 330 | 1.5 | 53 | 210 | 1050 |

| 60T | 46.8 | 420 | 1.5 | 53.5 | 260 | 1280 |

| 70T | 54.68 | 450 | 1.5 | 54 | 290 | 1600 |

| 80T | 62.5 | 630 | 2.2 | 54 | 1410 | 550 |

| 90T | 70.31 | 630 | 2.2 | 54 | 350 | 1650 |

| 100T | 78.12 | 700 | 3 | 54.5 | 1540 | 580 |

| 125T | 97.56 | 830 | 3 | 55 | 410 | 1700 |

| 150T | 117 | 950 | 3 | 55 | 600 | 1850 |

| 175T | 136.8 | 1150 | 3.75 | 55 | 890 | 2010 |

| 200T | 156.2 | 1250 | 3.75 | 55.0 | 920 | 2100 |

| 225T | 175.5 | 1500 | 5.5 | 52 | 1100 | 2870 |

| 250T | 195.12 | 1750 | 5.5 | 53 | 1200 | 2950 |

| 300T | 234 | 2000 | 7.5 | 53.5 | 1820 | 4050 |

| 350T | 273.24 | 2000 | 7.5 | 54 | 1890 | 4100 |

| 400T | 312.12 | 2400 | 11 | 54.5 | 2920 | 5900 |

| 500T | 392.4 | 2600 | 15 | 55 | 3010 | 5950 |

| 600T | 468 | 3750 | 15 | 56 | 4050 | 9450 |

| 700T | 547.2 | 3750 | 18.5 | 58.0. | 4180 | 9600 |

| 800T | 626.4. | 5000 | 22 | 59 | 4900 | 12100 |

| 1000T | 781.2 | 5400 | 22 | 59.5 | 5000 | 12300 |

| Designparameters:Inlet water temperature--T1=37-40ºC outlet water temperature-.T2=32ºC Wet bulb temperature-WBT=27ºC Water temperature drop--Ts=5-8ºC Atmospheric pressure.P=99400Pa | ||||||

| FRP Square Cooling Tower | ||||||||||||

| Model | Cell | DIMENSIONS | Fan (mm) | Motor (mm) | pressure kPa | Weight (KG) | Noise (16m) | DN1 | DN2 | |||

| A | B | H | ||||||||||

Standard Model | ZLSCL-80 | 80-C1 | 2280 | 2280 | 3535 | 1500 | 2.2 | 37 | 740 | 47.0 | 150 | 200 |

| ZLSCL-100 | 100-C1 | 2530 | 2530 | 3655 | 1800 | 4.0 | 38 | 1020 | 48.0 | 150 | 200 | |

| ZLSCL-125 | 125-C1 | 2830 | 2830 | 3785 | 1800 | 4.0 | 38 | 1270 | 49.0 | 150 | 200 | |

| ZLSCL-150 | 150-C1 | 3080 | 3080 | 3860 | 2000 | 4.0 | 39 | 1530 | 50.0 | 150 | 200 | |

| ZLSCL-175 | 175-C1 | 3330 | 3330 | 4060 | 2400 | 5.5 | 40 | 1840 | 51.0 | 150 | 200 | |

| ZLSCL-200 | 200-C1 | 3530 | 3530 | 4150 | 2800 | 7.5 | 42 | 2040 | 52.0 | 200 | 250 | |

| ZLSCL-225 | 225-C1 | 3730 | 3730 | 4220 | 2800 | 7.5 | 43 | 2400 | 53.5 | 200 | 250 | |

| ZLSCL-250 | 250-C1 | 3930 | 3930 | 4495 | 2800 | 7.5 | 44 | 2398 | 54.5 | 200 | 250 | |

| ZLSCL-300 | 300-C1 | 4330 | 4330 | 4765 | 3400 | 11 | 45 | 3760 | 55.0 | 250 | 300 | |

| ZLSCL-400 | 400-C1 | 4980 | 4980 | 5315 | 4200 | 15 | 49 | 5800 | 57.5 | 250 | 300 | |

| ZLSCL-500 | 500-C1 | 5580 | 5580 | 5685 | 4600 | 18.5 | 50 | 6480 | 58.5 | 300 | 350 | |

| ZLSCL-600 | 600-C1 | 6080 | 6080 | 5825 | 4600 | 22 | 52 | 7760 | 60.5 | 300 | 350 | |

| ZLSCL-650 | 225-C3 | 3730 | 11030 | 4220 | 2800 | 7.5x3 | 43 | 7220 | 61.0 | 200x3 | 250x3 | |

| ZLSCL-700 | 175-C4 | 3330 | 13080 | 4060 | 2400 | 5.5x4 | 40 | 7360 | 61.5 | 150x4 | 200x4 | |

| ZLSCL-800 | 200-C4 | 3530 | 13880 | 4150 | 2800 | 7.5x4 | 42 | 8180 | 62.0 | 200x4 | 250x4 | |

| ZLSCL-900 | 225-C4 | 3730 | 14680 | 4220 | 2800 | 7.5x4 | 43 | 9630 | 62.5 | 200x4 | 250x4 | |

| ZLSCL-1000 | 200-C5 | 3530 | 17330 | 4150 | 2800 | 7.5x5 | 42 | 10230 | 63.0 | 200x5 | 250x5 | |

| ZLSCL-1100 | 225-C5 | 3730 | 18330 | 4220 | 2800 | 7.5x5 | 43 | 12000 | 63.5 | 200x5 | 250x5 | |

| ZLSCL-1250 | 250-C5 | 3930 | 19330 | 4495 | 2800 | 7.5x5 | 44 | 11990 | 64.0 | 200x5 | 250x5 | |

| ZLSCL-1500 | 300-C5 | 4330 | 21330 | 4765 | 3400 | 11x5 | 45 | 18800 | 64.5 | 250x5 | 300x5 | |

Moderate temprature Model | ZLSCL II-80 | 80-C1 | 2280 | 2280 | 4035 | 1500 | 3.0 | 42 | 1140 | 56.0 | 150 | 200 |

| ZLSCL II-100 | 100-C1 | 2530 | 2530 | 4155 | 1800 | 4.0 | 43 | 1330 | 57.0 | 150 | 200 | |

| ZLSCL II-125 | 125-C1 | 2830 | 2830 | 4285 | 1800 | 4.0 | 43 | 1620 | 58.0 | 150 | 200 | |

| ZLSCL II-150 | 150-C1 | 3080 | 3080 | 4360 | 2000 | 5.5 | 44 | 1880 | 59.0 | 150 | 200 | |

| ZLSCL II-175 | 175-C1 | 3330 | 3330 | 4560 | 2400 | 7.5 | 45 | 2380 | 60.0 | 150 | 200 | |

| ZLSCL II-200 | 200-C1 | 3530 | 3530 | 4650 | 2800 | 7.5 | 47 | 2940 | 61.0 | 200 | 250 | |

| ZLSCL II-225 | 225-C1 | 3730 | 3730 | 4720 | 2800 | 7.5 | 48 | 3150 | 62.0 | 200 | 250 | |

| ZLSCL II-250 | 250-C1 | 3930 | 3930 | 4995 | 2800 | 7.5 | 49 | 3450 | 63.0 | 200 | 250 | |

| ZLSCL II-300 | 300-C1 | 4330 | 4330 | 5265 | 3400 | 11 | 50 | 4160 | 63.5 | 250 | 300 | |

| ZLSCL II-400 | 400-C1 | 4980 | 4980 | 5815 | 4200 | 15 | 54 | 6350 | 64.5 | 250 | 300 | |

| ZLSCL II-500 | 500-C1 | 5580 | 5580 | 6185 | 4600 | 18.5 | 55 | 7180 | 65.5 | 300 | 350 | |

| ZLSCL II-600 | 600-C1 | 6080 | 6080 | 6325 | 4600 | 22 | 57 | 9820 | 65.5 | 300 | 350 | |