-

Mobile Version

Scan with Mobile

- Member Center

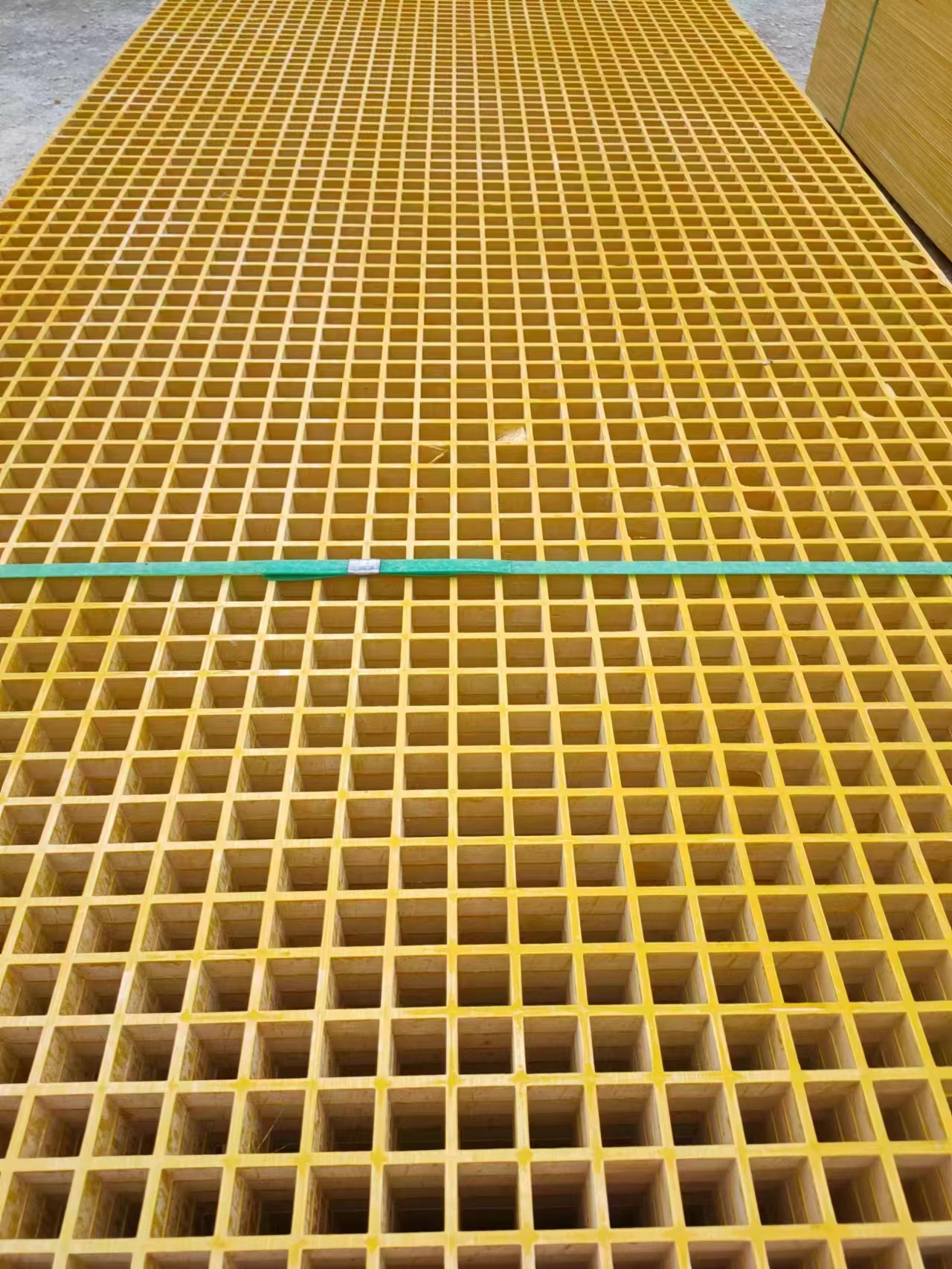

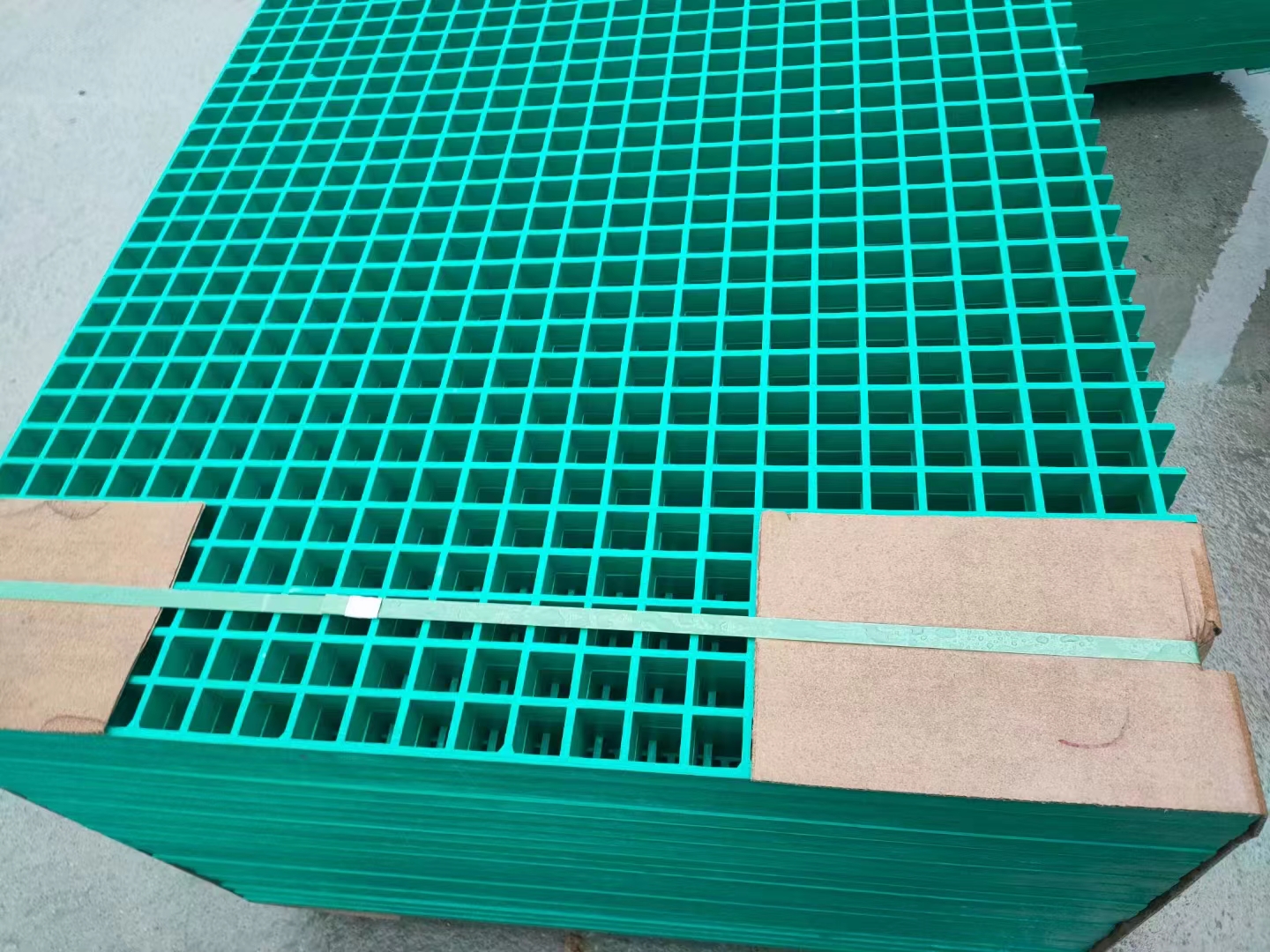

Cooling Tower FRP Parts

Fiber reinforced plastic (FRP), also known as fiber reinforced polymer, is in fact a composite material constituting a polymer matrix blended with certain reinforcing materials, such as fibers. The fibers are generally basalt, carbon, glass in certain cases asbestos, wood or paper can also be used.

Most of these plastics are formed through various molding processes wherein a mold or a tool is used to place the fiber pre-form, constituting dry fiber or fiber containing a specific proportion of resin. After ‘wetting’ dry fibers with resin, “curing” takes place, wherein the fibers and matrix assume the mold’s shape. In this stage, there is occasional application of heat and pressure. The different methods include compression molding, bladder molding, mandrel wrapping, autoclave, filament winding, and wet layup, among others.

The other exclusive properties of fiber reinforced plastics include commendable thermal insulation, structural integrity, and fire hardness along with UV radiation stability and resistance to chemicals and other corrosive materials.

The characteristics of fiber reinforced plastics are dependent upon certain factors like mechanical properties of the matrix and fiber, the relative volume of both these components, and the length of the fiber and orientation within the matrix.